EVENT

- Home

- company

- EVENT

Beyond Measurement: BARO’s Approach to GD&T

- 48

- 바로스튜디오

- 2026-02-06

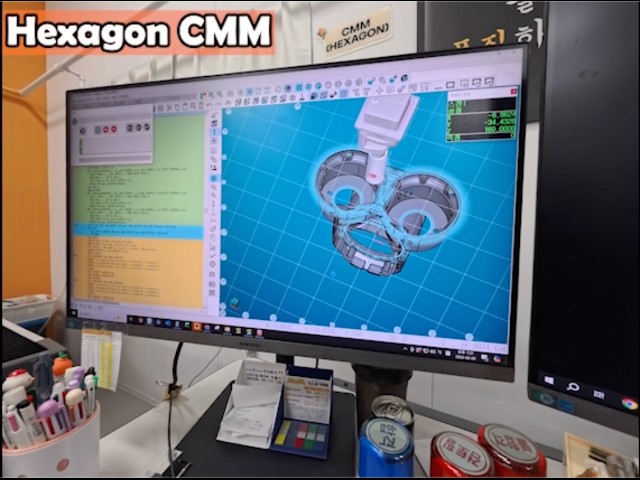

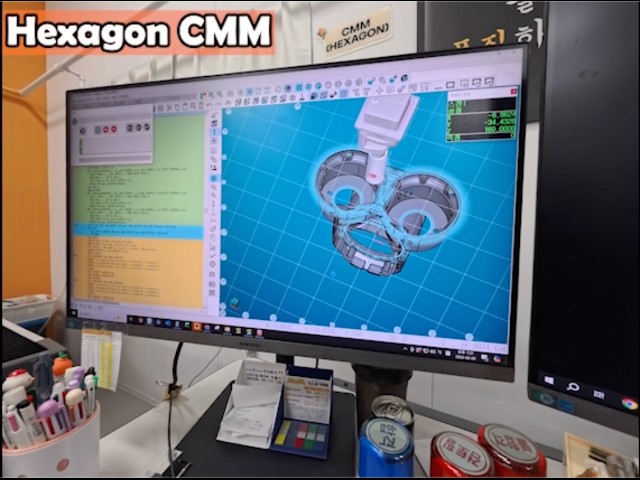

Click the image to see video

At BARO, GD&T measurement goes beyond simply operating a CMM. It starts with truly understanding the intent behind each tolerance.

Through extensive hands-on experience across countless projects, our team measures parts based on a deep understanding of GD&T requirements, not just numbers on a drawing.

BARO operates two CMM systems — Hexagon and Carl Zeiss — for a reason. When measurement results differ between suppliers and customers, we exchange measurement programs and verify whether both sides are evaluating parts under the same conditions. This allows us to identify gaps, align measurement methods, and continuously strengthen our quality know-how.

Because in precision manufacturing, measurement alignment is just as important as achieving accurate parts — whether machined or molded.

❌ No waiting. No time zones.

Try BARO’s 24/7 online quoting on our website.

At BARO, GD&T measurement goes beyond simply operating a CMM. It starts with truly understanding the intent behind each tolerance.

Through extensive hands-on experience across countless projects, our team measures parts based on a deep understanding of GD&T requirements, not just numbers on a drawing.

BARO operates two CMM systems — Hexagon and Carl Zeiss — for a reason. When measurement results differ between suppliers and customers, we exchange measurement programs and verify whether both sides are evaluating parts under the same conditions. This allows us to identify gaps, align measurement methods, and continuously strengthen our quality know-how.

Because in precision manufacturing, measurement alignment is just as important as achieving accurate parts — whether machined or molded.

❌ No waiting. No time zones.

Try BARO’s 24/7 online quoting on our website.

비밀번호 확인